- #Dual clutch transmission truck drivers

- #Dual clutch transmission truck driver

- #Dual clutch transmission truck manual

This is because the driver needs to time the shifting of the gears. Usually, these transmissions tend to need more effort from the driver.

#Dual clutch transmission truck manual

Unsynchronized transmissions, on the other hand, are the older model of manual gearboxes. Also, these transmissions help avoid double clutching.

#Dual clutch transmission truck drivers

This allows drivers to lock the gears without any problem. Synchronized gearboxes make sure that the gears rotate and mesh, as well as locking the shaft. Two Types of Transmissions: Synchronized and Unsynchronizedįor all types of vehicles, there are two main transmissions for manual gearboxes: synchronized and unsynchronized. Additionally, we’ll talk about automatic and AMT transmissions. That way, you can get a better picture of the gearbox types for trucks. In this article, we’ll go over the two main types of manual transmissions. Today, we’ll go over the main semi truck transmission types. By using your truck’s gearbox, you’re able to either speed up or slow down.

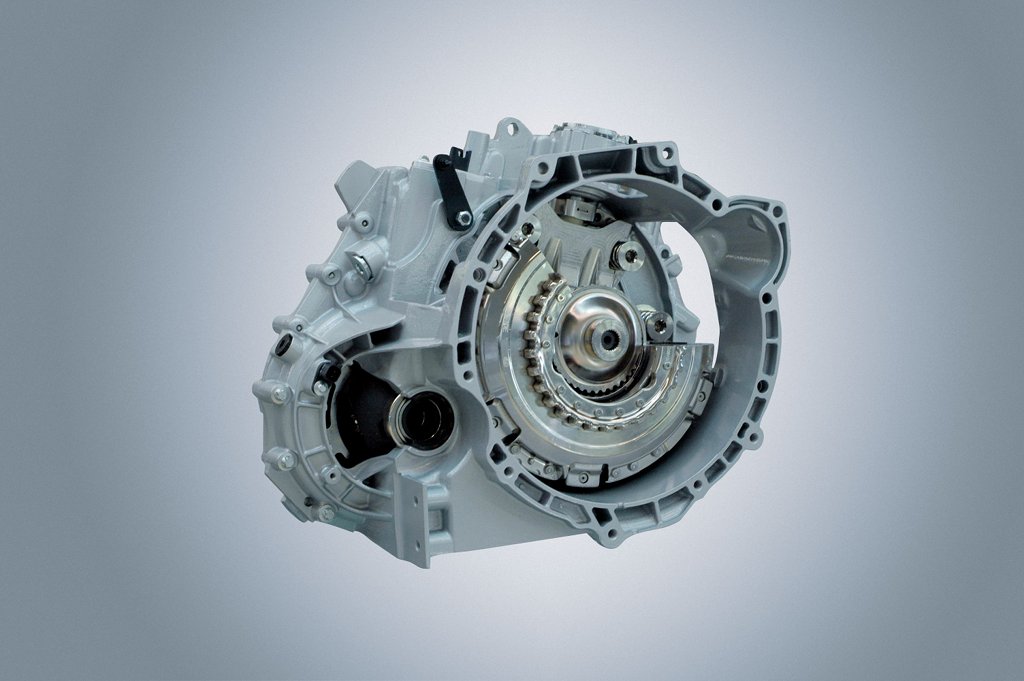

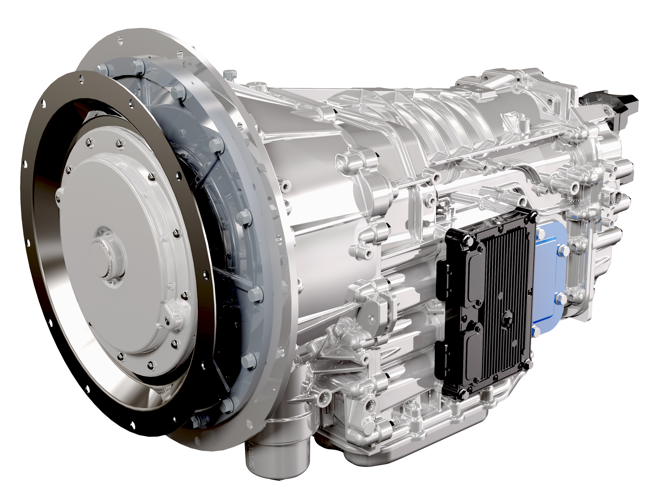

Image: I-Shift Dual Clutch can change gears without any interruption in power delivery, with the exception of the range-change, which takes place when shifting from sixth to seventh gear.These Are the Main Semi Truck Transmission TypesĪs you may know, a transmission is what ultimately powers your truck. The result is more relaxed and safe driving,” says Drewsen. Power-shift gear changes, where there is no interruption in power delivery, means it is easier to keep up with traffic, especially on difficult stretches of roads. The heavier the transport and the tougher the operating conditions, the more you will gain with I Shift Dual Clutch. “For trucks, this gearbox will truly make a major difference to driveability. As a result, engine torque is maintained and driving comfort is significantly improved,” says Astrid Drewsen, product manager for drivelines at Volvo Trucks. With dual clutches, gear changes take place without any interruption in power delivery. When one gear is selected in one gearbox, the next gear is already prepared in the other. “When driving, it feels like you have access to two gearboxes. I-Shift Dual Clutch is based on I-Shift, but the front half of the gearbox has been redesigned with entirely new components. It is the clutch that determines which of the gears is currently active. This means that two gears can be selected at the same time. I-Shift Dual Clutch is a transmission consisting of two input shafts and a dual clutch. “In situations that require a lot of gear changes, for instance on hilly or windy roads, I-Shift Dual Clutch brings an entirely new dimension to truck driving,” says Claes Nilsson, president of Volvo Trucks. For the driver, the result is more comfortable and efficient progress on the road. Thanks to power-shift gear changes, torque is maintained without any interruption in power delivery and, as a consequence, the truck does not lose any speed during gear changes. The Swedish commercial vehicle manufacturer is launching I-Shift Dual Clutch, the first automated transmission for heavy vehicles with a dual clutch system. Now Volvo Trucks is the first manufacturer in the world to offer a similar solution for series-produced heavy vehicles on certain Volvo FH models (with Euro-6 D13 engines with 460, 500 or 540 hp options) from end-2014.

Transmissions with dual clutches are already in use in cars.

0 kommentar(er)

0 kommentar(er)